Metallic Expansion Joints

The basic element of a Metallic Expansion Joint (MEJ) is the bellows - a flexible, corrugated tubular metal element to absorb movements in a piping system.

In the operating environment the critical stresses and movements may act in axial, lateral or angular directions and the bellows must therefore be designed and dimensioned to accommodate these movements.

Metallic Expansion Joints are broadly broken into Unrestrained Assemblies and Restrained Assemblies.

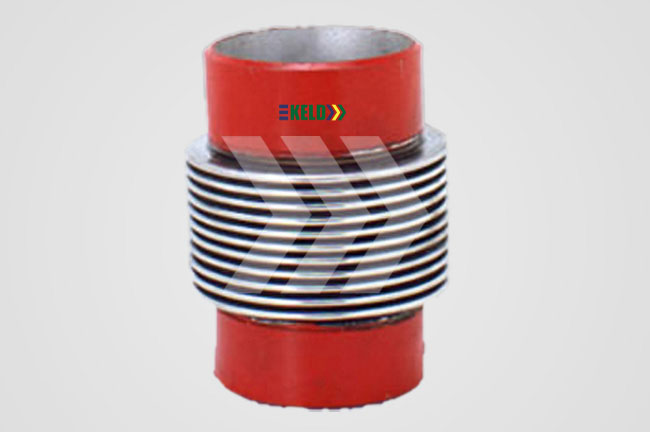

Single Bellow Assembly

The simplest type of expansion joint consists of a single bellow element welded to end fittings, normally flange or pipe ends. The single bellows can absorb small amounts of axial, lateral and angular movement with ease, but adequate anchors and guides must be provided.

Universal Expansion Joints Assembly

This assembly consists of two bellows connected by a center spool piece with flange or pipe ends. The universal arrangement allows greater axial, lateral and angular movements than a Single Bellow Assembly. Increasing the center spool length produces increased movement capability. Like the single, adequate anchors and guides must be provided.

Externally Pressurized Assembly

Line pressure acts externally on the bellows by means of a pressure chamber. This allows a greater number of convolutions to be used for large axial movements, without fear of bellows instability. Externally Pressurized Expansion Joints have the added benefit of self-draining convolutions if standing media is a concern. Anchors and guides are an essential part of a good installation.

Tied Single Bellow Assembly

The addition of tie rods to a Single Bellow Assembly adds design flexibility to a piping system. The tie rods are attached to the pipe or flange with lugs that carry the pressure thrust of the system, eliminating the need for main anchors. With the assembly tied, the ability to absorb axial growth is lost. The only lateral movement can be absorbed with the tied expansion joint.

Tied Universal Assembly

Similar in construction to a Universal Assembly except that tie rods absorb pressure thrust and limit movements to lateral offset and angulations. Large offset movements are possible in a Universal Assembly by increasing the distance between the two bellows.

Hinged Bellow Assembly

When a Hinged Expansion Joint is used, movement is limited to angulation in one plane. Hinged Assemblies are normally used in sets of two or three to absorb large amounts of expansion in high pressure piping system. Only low spring forces are transmitted to the equipment.

Gimbal Bellows Assembly

The gimbal restraint is designed to absorb system pressure thrust and torsional twins while allowing angulation in any plane. Gimbal Assemblies, when used in pairs or with a Single Hinged unit, have the advantage of absorbing movements in multi-planar piping systems. The gimbal works the same as an automobile universal drive shaft.